Introduction

The self loading concrete mixer is transforming small to mid-scale construction by integrating loading, mixing, and discharging into a single, autonomous unit. Unlike traditional mixers that rely on auxiliary equipment, this innovation enhances efficiency, reduces labor costs, and adapts to tight spaces—making it a cornerstone for modern contractors.

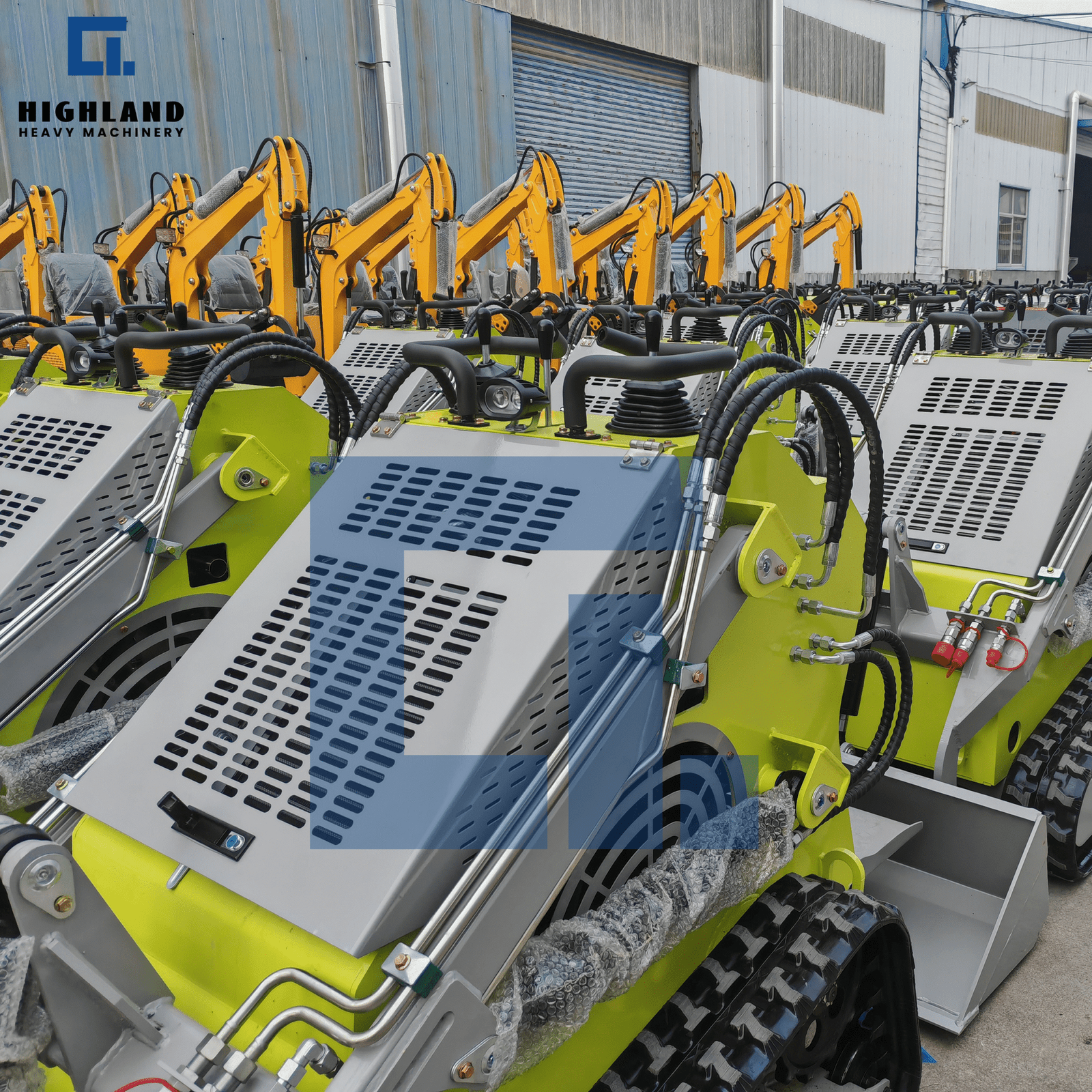

Key Advantages of Self Loading Concrete Mixers

1. All-in-One Operation & Labor Savings

Equipped with a built-in loader, these mixers eliminate the need for separate excavators or loaders by autonomously collecting aggregates, water, and cement. This integration cuts labor costs by 30–40% and shortens project timelines, making it ideal for budget-focused teams.

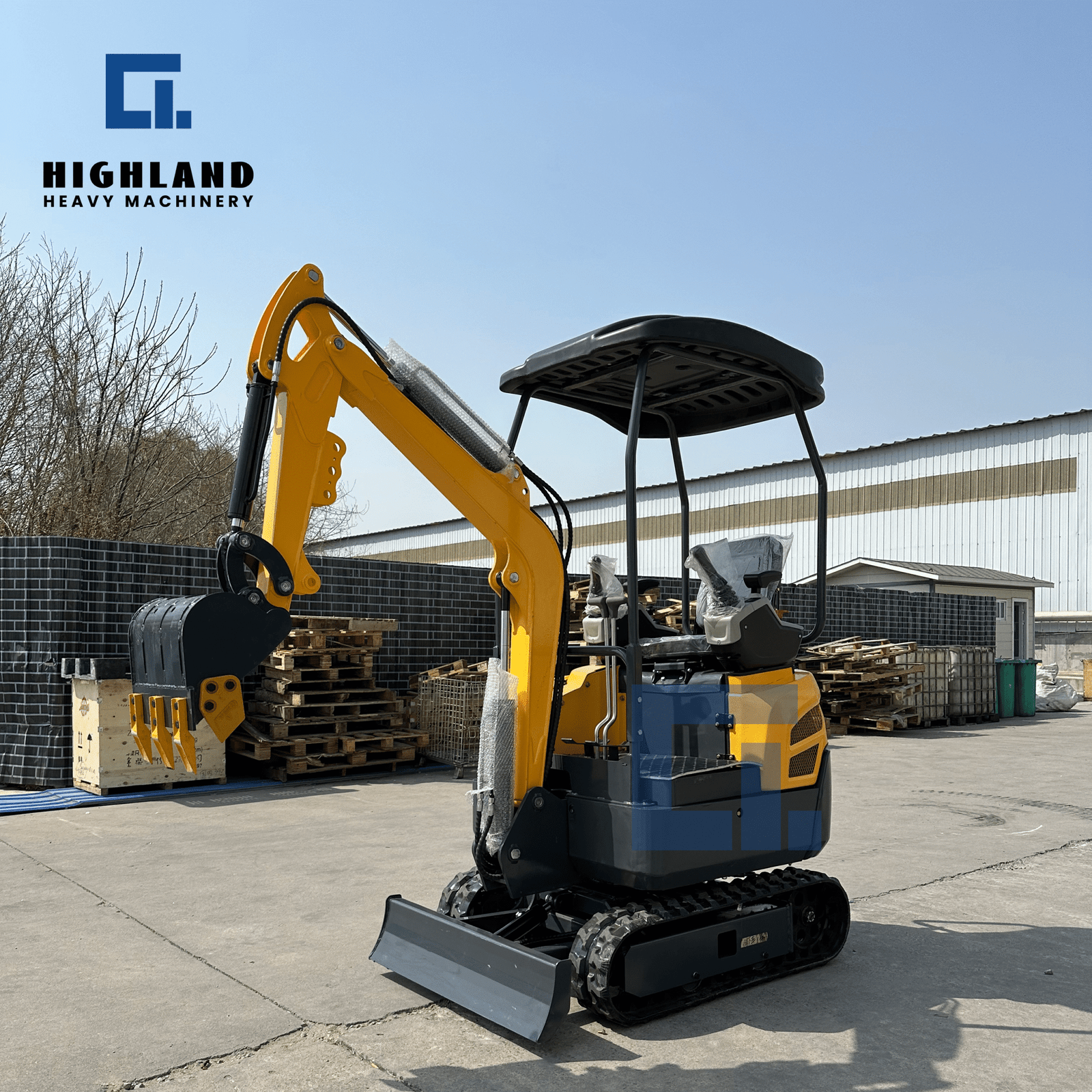

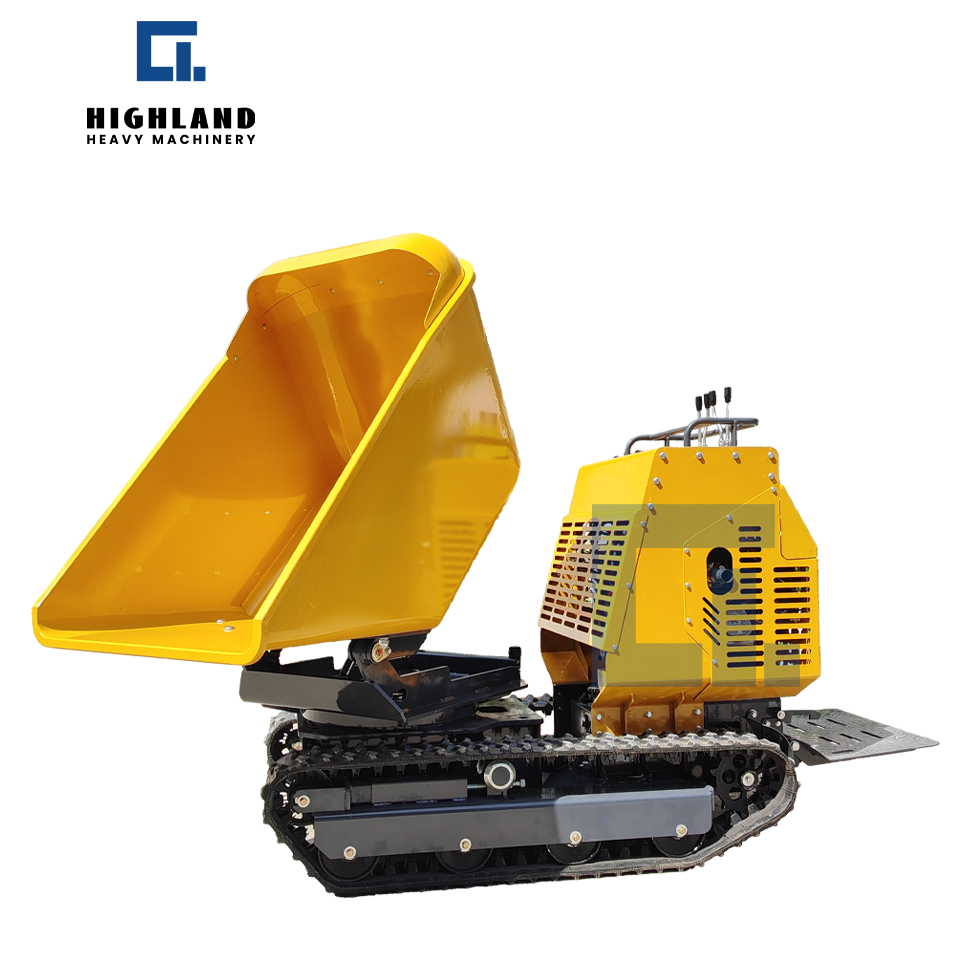

2.Compact Design for Versatile Access

With a typical length under 7 meters, self loading mixers navigate narrow urban alleys, rural roads, and unpaved paths—areas where large trucks struggle to operate. Their maneuverability ensures accessibility in both urban renovations and remote infrastructure projects.

3. Precision Control for Consistent Quality

Operators adjust mix ratios and drum rotation speed via intuitive control panels, ensuring uniform concrete quality critical for structural integrity. This precision minimizes material waste and reduces rework risks.

4. Cost Efficiency & Faster ROI

Lower fuel consumption and reduced dependency on multiple machines lower operational costs. Compared to traditional setups, these mixers offer a faster return on investment (ROI), particularly for small to mid-sized projects.

Top Applications of Self Loading Concrete Mixers

1. Small-Scale Construction Projects

Perfect for village house builds, backyard extensions, and garage constructions—where space and labor are limited. Their compact size and autonomous operation streamline on-site workflows.

2. Rural Infrastructure Development

Essential for rural road repairs, irrigation canal lining, and school renovations. They navigate unpaved terrain easily, supporting last-mile connectivity in remote areas.

3. Urban Renovation & Maintenance

Ideal for apartment upgrades, sidewalk repairs, and basement concrete pours. Their minimal footprint avoids disruption in crowded urban environments, reducing noise and traffic congestion.

4. Emergency & Rapid Repairs

Rapidly deployable for pothole fixes, flood-damaged road repairs, and disaster relief. They ensure quick concrete delivery and placement, critical for time-sensitive recovery efforts.

Conclusion

Self loading concrete mixers bridge the gap between large-scale machinery and manual mixing, offering unmatched flexibility, cost savings, and efficiency. For contractors prioritizing autonomy and ROI, this equipment is a transformative investment. By optimizing content with targeted keywords and clear structure, businesses can enhance visibility and attract high-intent customers searching for construction solutions.