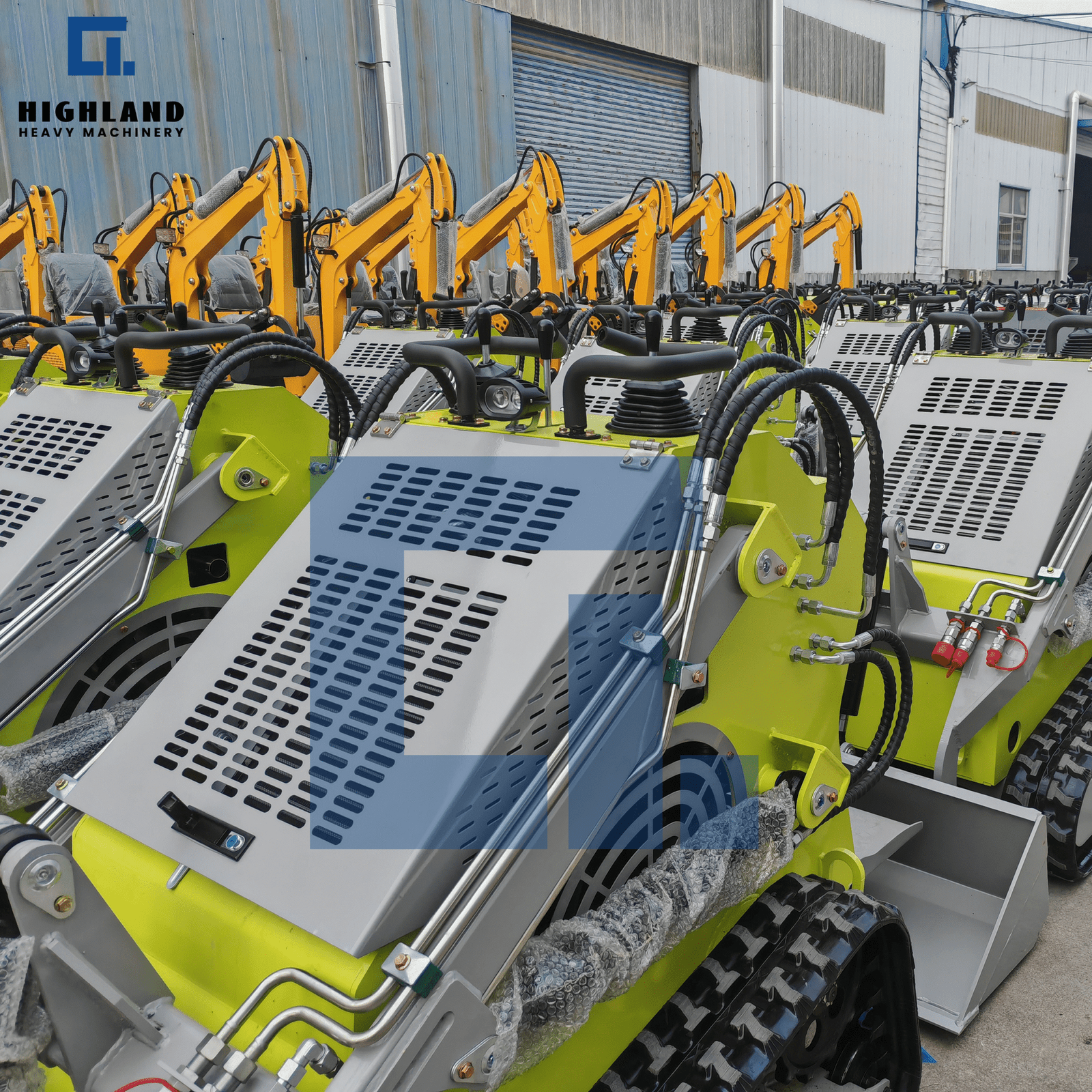

In the world of construction, agriculture, and urban development, size doesn’t always equal strength. The Mini Excavator—a compact, agile machine designed for precision in tight spaces—has emerged as a game-changer, outperforming traditional tools and even larger equipment in niche applications. This guide unpacks why Mini Excavators are becoming a staple across industries, highlighting their core advantages and versatile use cases.

4 Core Advantages: Why Mini Excavators Outshine the Competition

1. Compact Maneuverability: Navigate Where Larger Machines Can’t

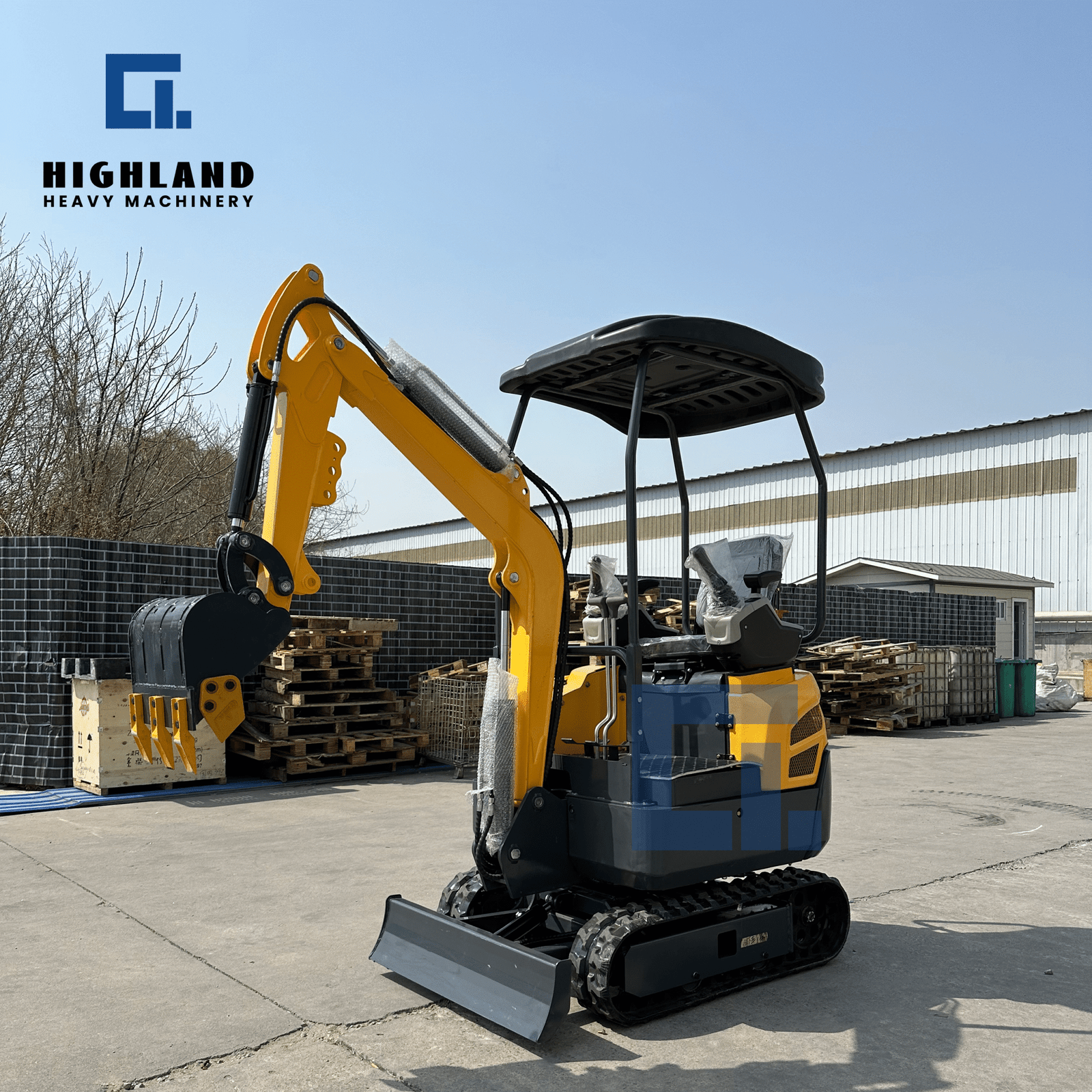

Mini Excavators are engineered for tight spaces, making them indispensable in confined environments. With typical dimensions of 2.8m (length) × 1m (width) × 2m (height) and a operating weight of 0.8–3 tons, they fit through narrow doorways, backyard gates, and urban alleyways. Their standout feature? A minimum turning radius of 1.3 meters (depending on the model), allowing 360° rotation on the spot for precise positioning. Tracked variants, equipped with rubber crawlers, glide over uneven terrain—slopes up to 30°, soft soil, or gravel—without damaging lawns, pavements, or delicate surfaces. This agility makes them ideal for residential areas, indoor sites, and crowded urban zones where full-size excavators would struggle to operate.

2. Cost-Efficiency: Maximize ROI with Lower Operating Costs

Mini Excavators deliver exceptional value through reduced expenses and higher productivity:

- Fuel & Energy Savings: Compared with large excavators, miniexcavators are more fuel-efficient.

- Minimal Maintenance: Simplified designs with accessible components (e.g., flip-up hoods, exposed hydraulic lines) reduce servicing time. Routine checks (oil, filters) take 15–20 minutes, and annual maintenance costs average 50% less than full-size excavators.

- Labor Reduction: By replacing manual digging (e.g., shovels, pickaxes), Mini Excavators complete tasks 3–5x faster. For example, digging a 10m trench that would take 2 workers 8 hours manually can be finished in 1 hour with a Mini Excavator, slashing labor costs by 60%+.

3. Versatility with Attachments: One Machine, Multiple Roles

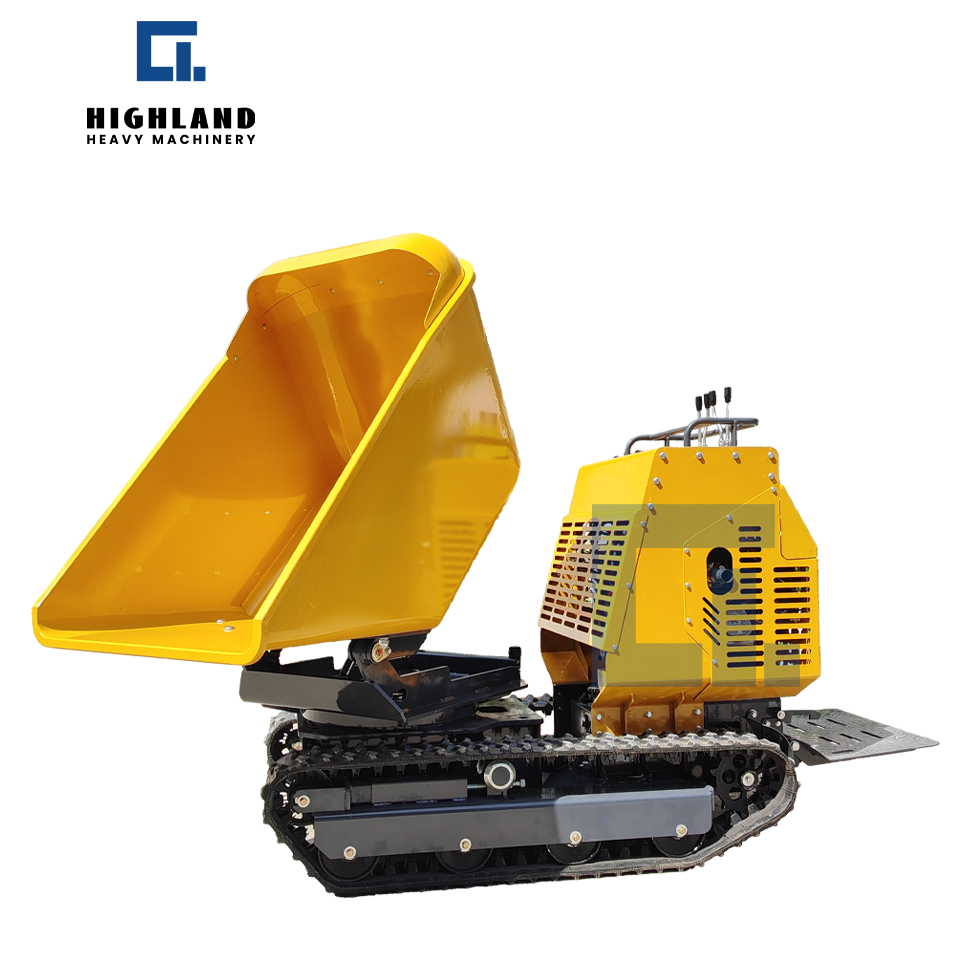

What truly sets Mini Excavators apart is their compatibility with a wide range of attachments, transforming them into multi-functional tools:

- Standard Attachments:

- Digging Buckets(0.03m³-0.05m³ capacity): For soil, sand, or gravel excavation.

- Hydraulic Breakers: Ideal for breaking concrete, asphalt, or rock in renovation projects.

- Augers: Drill holes for fence posts, tree planting, or utility poles (diameters 100–300mm).

- Grapples: Handle debris, logs, or loose materials like branches or construction waste.

- Specialized Tools: Trenchers (for narrow utility lines), rakes (landscaping grading), and even snow blades (winter maintenance).

This versatility eliminates the need for multiple machines, making Mini Excavators a cost-effective choice for small businesses and contractors.

- Specialized Tools: Trenchers (for narrow utility lines), rakes (landscaping grading), and even snow blades (winter maintenance).

4. Easy Operation: Intuitive Controls for All Skill Levels

Mini Excavators prioritize user-friendliness, ensuring operators—even those with minimal experience—can get to work quickly:

- Simplified Controls: Pilot-operated joysticks replace complex levers, allowing precise movement of the boom, arm, and bucket with minimal effort.

- Safety Features: Retractable seatbelts, ROPS (Roll-Over Protective Structure) cabs, and anti-slip steps reduce accident risks. Many models include rearview cameras for blind-spot visibility.

- Low Training Threshold: Basic operation can be mastered in 1–2 hours(vs. days for full-size excavators), with no need for specialized certifications (depending on local regulations). This makes them accessible to homeowners, farmers, and small teams.

5 Key Applications: Where Mini Excavators Excel

1. Residential Landscaping: Crafting Outdoor Spaces with Precision

For homeowners and landscapers, Mini Excavators tackle tasks like:

- Digging ponds, trenches for irrigation lines, or foundations for patios/decks.

- Removing tree stumps (with stump grinders) or boulders (with grapples).

- Grading soil for lawns or flower beds, ensuring even terrain for planting.

Their compact size avoids damaging existing landscaping, and rubber tracks protect lawns from ruts—critical for maintaining curb appeal.

2. Urban Renovations: Navigating Tight City Spaces

In crowded urban areas, Mini Excavators shine in:

- Utility Work: Digging narrow trenchesfor water pipes, electrical cables, or sewer lines along sidewalks or alleyways.

- Demolition: Breaking up old concrete slabs, driveways, or interior walls in apartment renovations (paired with a breaker attachment).

- Site Prep: Clearing debris from small construction sites (e.g., backyard ADU builds) where access is limited by buildings or power lines.

3. Agricultural Work: Boosting Farm Productivity

Farmers rely on Mini Excavators for year-round tasks:

- Digging drainage ditches to prevent waterlogging in fields.

- Cleaning out manure from barns (with grapples) or excavating root cellars.

- Preparing soil beds for planting by loosening compacted earth (with a rotary tiller attachment).

Their ability to operate on soft, muddy ground (thanks to tracked undercarriages) makes them ideal for rural environments.

4. Indoor Projects: Safe, Low-Impact Operation

Unlike large machinery, Mini Excavators are suited for indoor jobs:

- Commercial Renovations: Demolishing walls or excavating basements in malls, hospitals, or offices.

- Warehouse Upgrades: Digging trenches for floor drains or utility lines without damaging concrete slabs (rubber tracks prevent scratches).

- Industrial Maintenance: Accessing tight spaces in factories to repair machinery or clear production waste.

5. Emergency Response: Rapid Action in Crisis Scenarios

In disasters or emergencies, Mini Excavators provide critical support:

- Natural Disasters: Clearing debris from earthquakes, floods, or storms in residential areas where heavy equipment can’t reach.

- Roadside Emergencies: Repairing potholes, clearing fallen trees, or digging around damaged utility poles to restore services.

- Search & Rescue: Gently moving rubble in collapsed structures to locate survivors (with grapple attachments for precise handling).

How to Choose the Right Mini Excavator

When selecting a Mini Excavator, consider:

- Size & Weight: Match to your workspace (e.g., 1–2 ton models for indoor use, 3–5 ton for heavy outdoor tasks).

- Power Source: Diesel for high torque (outdoor, heavy duty); electric for zero emissions (indoor, residential).

- Attachments: Prioritize models with quick-attach systems for easy tool swaps.

Conclusion: Mini Excavators—Small in Size, Big on Impact

The Mini Excavator has redefined what’s possible in compact construction, offering unmatched maneuverability, cost savings, and versatility. Whether you’re a landscaper, farmer, contractor, or emergency responder, this machine delivers efficiency and productivity in spaces where larger equipment can’t tread. As small-scale projects continue to grow, the Mini Excavator remains an investment that pays dividends in time, labor, and results.